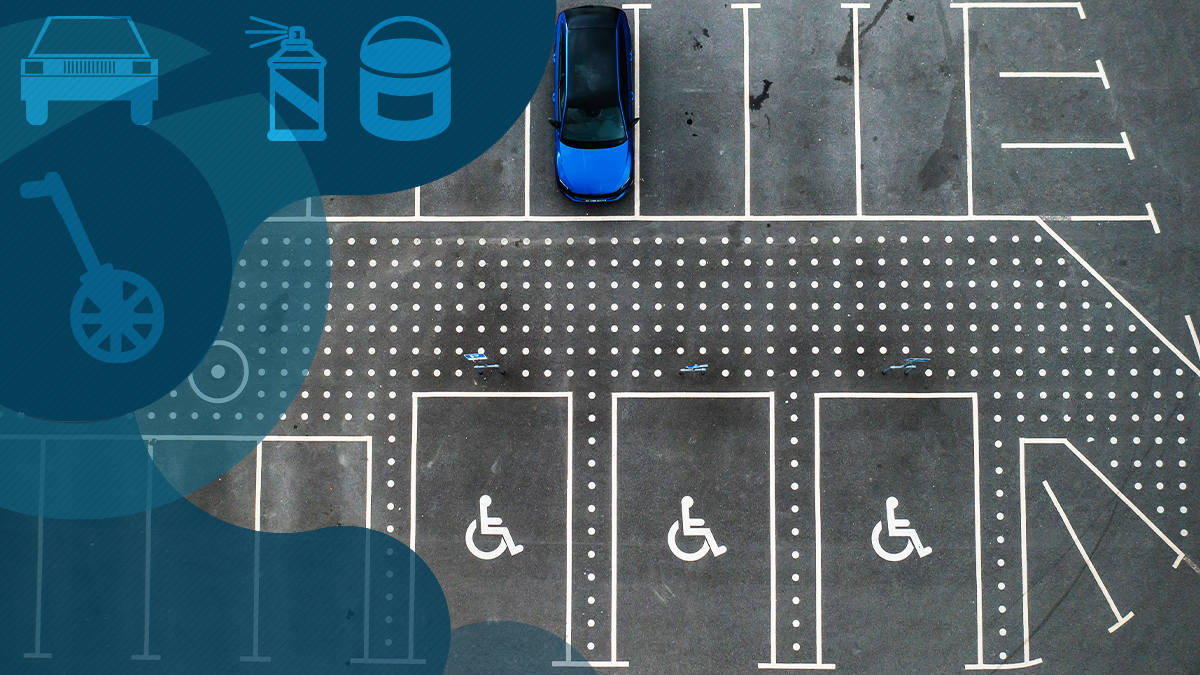

ADA Parking Striping Compliance to Prevent Callbacks

Avoid costly rework with ADA parking striping that passes inspection. Learn the layout rules, compliance tips, and tools to get it right the first time.

ADA parking striping looks simple, but most profit loss happens here.

A stall that’s one inch off. An access aisle that doesn’t line up with the entrance. A sign that doesn’t match local code.

These small misses create callbacks, rework, and schedule friction.

Not because the paint failed, but because the layout didn’t meet compliance.

Getting ADA parking striping right the first time protects margin and avoids free labor spent correcting work that looked “done.”

“The layout tells the story on inspection day. If the spacing, aisle, and route make sense, everything else falls into place.”

— Ryan Masotti, Industry Specialist at SONCO

Common Compliance Mistakes Contractors Run Into

Most ADA callbacks happen before the paint is even dry. The issue is layout, not the striping work.

- Stall and Access Aisle Width

Measurements vary by state. Even small gaps lead to rework.

- Sign Placement and Height

Paint may be correct, but missing or misaligned signage fails inspection.

- Route to Entrance

The accessible stall must connect to a clear path to the main entrance. If not, it’s marked wrong.

- Van Accessible Marking

Contractors often note the symbol, but skip the additional width or signage tag.

These are simple details, but they are the ones that cost crews time, disrupt schedules, and reduce margin when missed.

Why These Mistakes Cost Contractors Money

Rework is where profit slips. Once the crew has to return, the job is no longer profitable.

The impact shows up in:

- Extra labor working the same job twice.

- Lost schedule time that delays the next site.

- Higher fuel and equipment hours for a non-billable visit.

- Frustration from the property manager, which affects repeat work.

- Tighter margins across the entire week’s workload.

Real Cases Where ADA Parking Striping Led to Costly Rework

Small layout errors can become real financial problems. These cases show what happens when ADA striping doesn’t meet compliance.

In Midland, TX, dozens of local businesses faced ADA settlements ranging from $6,500 to $9,500 because parking lot markings and signage did not meet ADA layout standards.

Law firms report that many ADA claims target parking lots with incorrect stall widths, missing van-accessible signage, or misaligned access aisles. These issues often lead to settlements even when the rest of the site is compliant.

Field reports show common failure points: access aisles that don’t connect to the entrance route, wrong signage height, and missing van-accessible markings. These issues require restriping and rework after inspection.

Pavement coating and maintenance experts report that improper or faded ADA striping can expose property owners to legal claims, not just code citations.

The Practical Fix: Plan Compliance Before Striping Begins

A quick check before work starts prevents callbacks and protects margin.

- Confirm Stall and Aisle Measurements

Check width, length, and aisle pairing against local requirements. Some states add rules beyond federal ADA.

- Verify Path to the Entrance

The accessible stall must connect to a clear route to the main entrance. If not, the layout needs adjustment before paint.

- Align Signage With the Marked Stall

The symbol, the aisle, and the sign all work together. When one is out of place, the job fails inspection.

- Plan Work Zone Control

Clear the area and block vehicle entry. Disruption during layout leads to mistakes.

Taking five minutes to confirm layout and signage placement is often what protects the job from rework.

Products That Support ADA Compliant Parking Lot Striping

ADA mistakes happen in the layout phase, SONCO supplies the tools to get it right the first time.

These products help crews layout and stripe ADA stalls cleanly, stay within spec, and avoid callbacks.

- Traffic Paints

Water-based and thermoplastic paints designed for high visibility and durable pavement markings.

- Aerosol Striping Paint

Fast-dry cans for touch-ups, small lots, and tight areas.

Useful when the crew needs clean lines without bringing full sprayers.

- Marking Stencils (ADA + Symbols)

Reusable polyvinyl stencils, including:

- ADA Handicap Symbol

- VAN ACCESSIBLEArrows and directional markings

- EV Charging symbol (growing demand)

Keeps dimensions consistent across different jobs and teams.

- Striping Machines & Applicators

From simple paint wands to wheeled striping machines for larger lots.

Supports straight line accuracy and reduces paint waste.

- Measuring & Layout Tools

Chalk line reels and measuring wheels help crews confirm distances and aisle widths before paint touches pavement.

- Supplementary Parking & Traffic Safety Products

Speed bumps, parking stops, reflective markers, and MUTCD-compliant signage.

Helps contractors offer a full project, not just lines — which increases ticket value.

Why Contractors Work with SONCO

Striping work moves fast. Schedules change, weather shifts, and sites open without notice. Contractors choose SONCO because the materials they need are in stock and ready to ship.

- Consistent Availability

Traffic paint, stencils, signage, and layout tools stay stocked so crews don’t wait on suppliers.

- Support When You Need It

Our team works directly with contractors to match materials to the job, not just the order.

- Nationwide Shipping

Products ship from multiple locations to keep projects moving, even when timelines are tight.

When ADA parking striping comes down to accuracy and timing, having the right materials on-site is what protects margin and keeps the schedule on track.

Get Materials That Support ADA Striping Work

SONCO supplies traffic paint, stencils, signage, and layout tools that help crews deliver clean, compliant ADA parking striping without rework.

Reach out at sales@soncostore.com or call 866-254-6510 to get pricing and shipping options.

Trend now

Theme Park Safety: Avoiding Fines and Accidents with Crowd Control

Learn how crowd control products help keep theme parks safe, avoid accidents, and improve operations. Explore SONCO’s solutions for better crowd management.

Anti Scale Fence for Temporary High-Security Needs

Learn what an anti scale fence is, how it works and when to use one. Covers climb resistance, projectile protection, accessories and deployment best practices.

Why Bike Rack Barricades Are the Go-To Choice for Crowd Control

Explore why bike rack barricades are the go-to for crowd control. Learn how these versatile, durable barriers keep events, construction sites, and more organized.